Since the transformer can be used in both directions, we can use two different balancing methods depending on the situation. For the controlling circuit, firstly detects the voltages of batteries one by one, calculates the average value, and then finds the battery whose voltage deviates the most from the average value. If the voltage of this battery is lower than the average value, take the lower limit balancing method; if it is higher than the average voltage, take the upper limit balancing method.

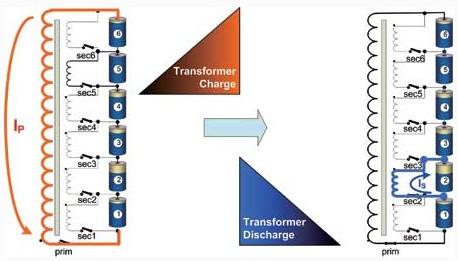

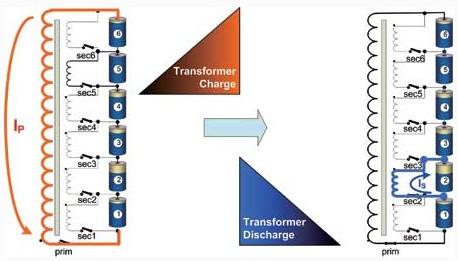

1. Balance of lithium power pack lower limit

The figure shows the situation where the lower limit balancing method is needed, where battery No. 2 is identified as the battery with the lowest voltage and needs to be replenished. Close the main winding switch and the battery pack is charged to the transformer. Then disconnect the main winding switch, close the corresponding secondary winding switch, and the energy stored in the transformer is transferred to the designated battery.

Each cycle consists of 2 active pulses and 1 interval. The period in this case is 40ms, which corresponds to a frequency of 25kHz. The transformer should be designed to operate at a frequency higher than 20kHz to avoid noise caused by the magnetoelasticity of the transformer core. The lower limit balancing method can extend the operating time of a lithium power pack when the charge state of a particular cell reaches the lower limit. As long as the current flowing out of the battery pack is lower than the average balance current, the vehicle can continue to drive until the last battery gets drained.

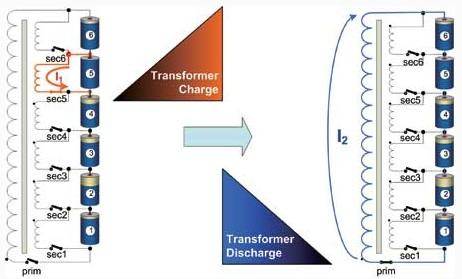

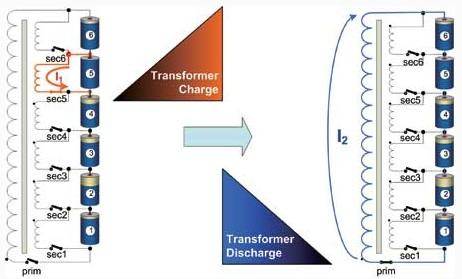

2. Balance of lithium power pack upper limit

If the voltage of a certain battery is higher than other batteries, it is necessary to remove the excess energy from that battery, which is especially necessary for charging mode. If there is no balancing function, then the charging must be stopped immediately after the first battery is full. The balancing function allows the voltage of all cells to be maintained at the same level, thus avoiding the above scenario.

The example shown in the figure illustrates the flow of energy in the upper limit balancing mode. After voltage detection, the No. 5 cell is considered as the highest voltage cell in the battery pack. Close the No. 5 secondary winding switch and current flows from battery No. 5 to the transformer. The current increases linearly with time due to the inductive effect. Given that inductance is a fixed characteristic of the transformer, the maximum current value is determined by the time the switch is closed. The energy transferred from the No. 5 battery is stored in the transformer's magnetic field. The No. 5 secondary winding switch is disconnected and the main winding switch is closed, at which point the transformer shifts to generator operation mode and the energy is fed into the lithium power pack through the large primary winding. The current and timing in the upper limit balance operating mode is similar to the lower limit balance, except that the sequence of operation and current flow is reversed.

(1) Balancing power

Using the prototype configuration, the average balancing point of six bits 5A is 50 times higher than the passive method, while the 5A balancing current generates only 2W of power consumption in the whole battery block. Therefore, this balancing method does not require special cooling measures, while improving the energy balance of the system.

(2) Voltage detection

In order to manage the state of charge of each battery, the voltage of each battery has to be measured. Since only cell No. 1 is within the analog-to-digital conversion range of the microcontroller, the voltages of the other cells in the battery block cannot be measured directly. One possible solution is to use a differential amplifier array, but this requires maintaining the voltage level of the entire battery block.

A proper battery management system can take full advantage of the new lithium power pack. Active charge balancing systems perform significantly better than the traditional passive approach. The creative use of simple transformers effectively reduces material costs.

EN

EN